Mineral Agitation Tank, Mixing Tank with Agitator for Flotation Machine

Basic Info

| Model NO. | Agitation Tank |

| Automation | Automatic |

| Warranty | 24 Months |

| Customized | Customized |

| Condition | New |

| Transport Package | Standard Transport Packing |

| Specification | Agitation Tank |

| Trademark | JINMA |

| Origin | China |

| HS Code | 84304900 |

Product Description

Company introductionHebei Jinma Mine Machinery Group is a professional manufacturer of "Jinma" metallurgical, mine, construction material and environmental equipment assemblies. Founded in 1971 and reorganized into a joint stock enterprise in 1997, the company consists of Tangshan Mine Machinery Plant, Tangshan Jinma Construction Material Machinery, Zunhua Jinma Environmental Equipment and Zunhua Jinma Mining The company covers 50 plus mu of land, with total assets of RMB90 million, some 600 employees including 96 engineering professionals and a variety of processing and testing devices, including large-size processing devices like 10t electric arc furnaces, vacuum casting tools, 8m, 5m and 4m vertical lathes, 8m, 5m and 3.15m hobbing machines, 6m planing machines, fine boring machines and medium-frequency quenching tools, and automatic welding, ultrasonic weld testers, W15-23 material testers and time-dependent vibrators totaling over 300 pieces of equipment. The company is conveniently situated in the delta of Beijing, Tianjin and Tangshan where it is endowed with advantaged physical location and sound accessibility. Our president Mr. Duan Zhiyu and general manager Ms. Duan Chunhong together with all the company staff are looking forward for cooperating with all friends in and out of China.

Introduction

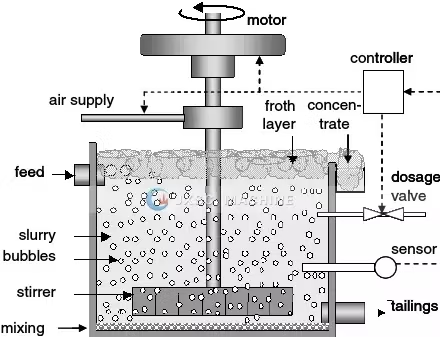

The impeller of agitation tank is driven by the motor and motor v-belt or gear motor, making the solid particles to suspend and making agent and ore pulp mixed adequately. It has four functions: ore pulp agitation, agitation storage tank, improving agitation and agent agitation. Agitation tank is suitable for ore dressing industry and can also be used in agitation of pulps from other industries.

Features

This product is the currently most frequently used normal agitation tank. The impeller is located at the lower opening of circulation column, feeding the ore pulp and agents into the circulation column with suction pore for agitating.

Main applications:

Used in mixing of ore pulp (concentration ≤ 30%, ore density < 3.5, solid particle size < 1mm) and flotation agent, and also used in pulp agitation of other non-metallic ores.

The tank is divided into cone base and flat base.

Parameter

Models | Specifications | Effective volume | Diameter of impeller | Revolution of impeller | Driving motor | Weight | |

Models | Power | ||||||

mm | m³ | mm | r/min | kw | t | ||

XB-1000 | Ф1000×1000 | 0.58 | 240 | 530 | Y90L-6 | 1.1 | 0.685 |

XB-1500 | Ф1500×1500 | 2.2 | 400 | 320 | Y132S-6 | 3 | 1.108 |

XB-2000 | Ф2000×2000 | 5.46 | 550 | 230 | Y132M2-6 | 5.5 | 1.5 |

XB-2500 | Ф2500×2500 | 11.2 | 650 | 280 | Y200L-6 | 18.5 | 3.46 |

XB-3000 | Ф3000×3000 | 19.1 | 700 | 210 | Y225S-8 | 18.5 | 5.19 |

XB-3500 | Ф3500 ×3500 | 30 | 850 | 230 | Y225M-8 | 22 | 6.86 |

XB-3550 | Ф3550×3550 | 31.5 | 850 | 230 | Y225M-8 | 30 | 7.28 |

XB-4000 | Ф4000×4000 | 45 | 1000 | 210 | Y280S-8 | 37 | 12.51 |

Corporate Style:

The company is conveniently situated in the delta of Beijing, Tianjin and Tangshan where it is endowed with advantaged physical location and sound accessibility. Our president Mr. Duan Zhiyu and general manager Ms. Duan Chunhong together with all the company staff are looking forward for cooperating with all friends in and out of China.

FAQ to save your precious time!

Q1: What's the standard length of your profiles and tube?

A: The standard length of profiles and tube are 5800mm to suit for small container, and we also can cut to specific length, however a surcharge of machining and material scrap cost will be charged accordingly based on each individual invoice.

Q2: What's your MOQ?

A: we have no MOQ for our new customers, however a surcharge of USD80 will apply for all orders less that USD 1000 for custom handing cost purpose.

Q3: what is your payment terms?

A: The payment terms we accept is T/T or irrevocable L/C at sight, T/T preferred.

Q4: What's the lead time for small order and mass production?

A: 1-3 working days for small order, and 3-10 working days for mass production of material, and the final lead time will be subject to each individual invoice.

Q5: What certification do you have?

A: We have ISO 9001:2008 certificate.