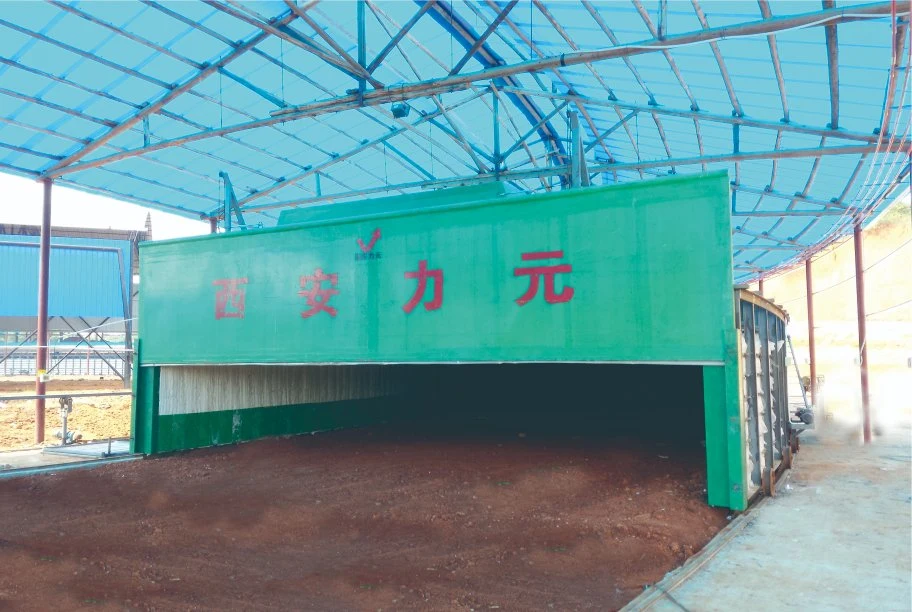

Movable Tunnel Kiln in Vietnam for Liyuan Kiln Automation Equipment

The movable tunnel kiln is the key thermal equipment for the sintered brick process system. It belongs to the sintered b

Basic Info

| Model NO. | LYKILN |

| After-sales Service | 1year |

| Warranty | 1year |

| Certification | CE, ISO |

| Customized | Customized |

| Automatic Grade | Automatic |

| Type | Hydraulic Shock |

| The Center Line Diameter of Kiln Bottom | 125 |

| The Net Width of The Kiln Room(M) | 12 |

| Rail Gauge(M) | 12.8 |

| The Distance of Kiln Shed Column(M) | 19 |

| The Min. Outer Diameter of The Circular | 154 |

| The Center Line Length of Kiln Body(M) | 150/168 |

| Stacking Layers for Green Bricks / Heigh | 12/1.5 |

| 10,000 PCS/Day (Standard Brick) | 30-33 |

| Transport Package | Brick Tunnel Kiln |

| Specification | YDY125/12 |

| Trademark | LiYuan |

| Origin | China |

| Production Capacity | 20PCS/Years |

Product Description

The movable tunnel kiln is the key thermal equipment for the sintered brick process system. It belongs to the sintered brick equipment that the green brick does not move and the kiln body moves circumferentially on the circular orbit. It mainly consists of equipment foundation, kiln body, thermal system, moisture-removing system, transportation system, power supply and control system, and annular flue, etc.The effect drawing of movable tunnel kil

The detailed drawing of movable tunnel kiln

The parameter table of movable tunnel kiln

Parameter specification | YDY100/8 | YDY125/8 | YDY150/8 | YDY125/12 | YDY150/12 |

The center line diameter of Kiln bottom (m) | 100 | 125 | 150 | 125 | 150 |

The net width of the kiln room(m) | 8 | 8 | 8 | 12 | 12 |

Rail gauge(m) | 8.8 | 8.8 | 8.8 | 12.8 | 12.8 |

The distance of kiln shed column(m) | 15 | 15 | 15 | 19 | 19 |

The Min. outer diameter of the circular kiln road(m) | 125 | 150 | 175 | 154 | 179 |

The center line length of kiln body(m) | 150/168 | 150/168 | 150/168 | 150/168 | 150/168 |

Stacking layers for green bricks / height of kiln room (m) | 12/1.5 | 12/1.5 | 12/1.5 | 12/1.5 | 12/1.5 |

10,000 Pcs/day (standard brick) | 20 | 20-23 | 20-25 | 30-33 | 30-35 |

Total power of fans(kw) | ≤119 | ≤119 | ≤119 | ≤208 | ≤208 |

| Thermal parameter measurement and control | Digital display, manual control / single board patrol monitor, manual control / automatic control is an optional feature that is available | ||||

Environment protection desulfurization device | Providing technical parameters, recommended use, matched by users' choice | ||||

Technical requirements: The moisture content of green brick should be not more than 16%, and the forming pressure is not less than 3.5Mpa, and the drying sensitivity coefficient of raw material is less than 1, and the total internal combustion heat consumption is less than 300 kcal / kg Explanation: The above data are reference values, and the specific parameters of the kiln are based on the results of raw material test and are tailor-made for customers. | |||||

The advantages of movable tunnel kiln

1, Lower production cost:Lower heat consumption, lower electricity, less labor, no kiln cart and ferry cart, lower comprehensive production cost. 2, Simple process flow, simple production management: One-time stacking process, double drying, real-time temperature monitoring, simple operation flow, high rate of good products, easy management for less labor 3, Green environmental protection: It fully responds to national environmental protection requirements and provides professional related environmental protection design. 4, Shorter construction period: The kiln construction period is only 90 days. 5, Shorter investment payback period: Lower investment, higher production capacity, lower production cost and shorter investment payback period.

6, Lower maintenance cost: High-standard and Targeted using materials , professional and excellent factory production, higher requirements of construction technology and construction accuracy to ensure that the equipment has not been overhauled for ten years.

Send to us